Responsiveness and customer service yield better conductor accessory solutions for AFL’s customers

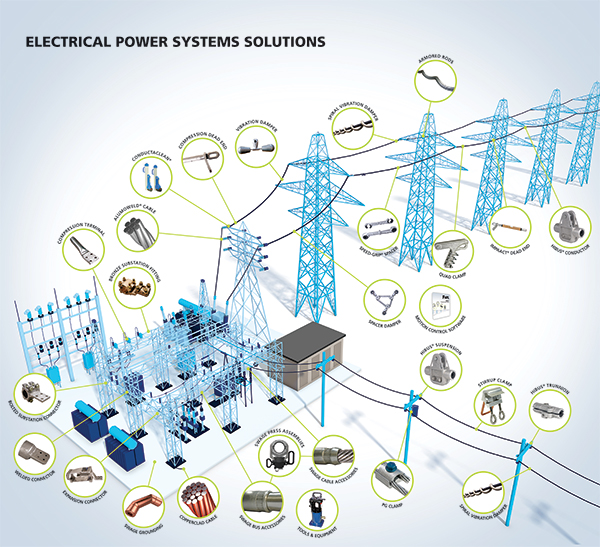

AFL’s conductor accessories provide superior performance and reliability for electric power utilities and rail companies. Drawing on the experience gained from over 80 years designing and manufacturing accessory products, AFL’s conductor accessories improve the reliability of critical electrical and optical infrastructure used for the transmission and distribution of electricity.

Our products are manufactured in Duncan, SC in a facility that is certified to ISO 4001 and ISO 9001:2015 standards. AFL's product offering includes the following:

- Substation accessories – include supports, couplers, connectors, expansions, taps, terminals, reducers, bus vibration dampers, stud connectors, end plugs and hardware. Available in standard compression, Swage bus, cable and grounding accessories for voltages up to 500 kV and traditional bolted and welded accessories for voltages of 230 kV in aluminum and bronze, 345/500 kV and 765 kV.

- Substation – bus conductors (round, integral web, rectangular bar, channel, universal angle bus, and rectangular bar).

- Compression accessories – Hi-Temp® compression, standard compression, quick compress and IMPACCT® (Implosive Accessory Technology)

- Fiber optic cable hardware – dead ends, suspensions, tangents, splice enclosures, snow shoes, attachment hardware and come-a-longs

- Motion control – stockbridge-type vibration dampers, spacers, spacer dampers and software for Aeolian vibration protection

- Wire products – strand and solid wire

- Formed Wire – ties, dead ends and armor rods

- Network underground accessories – multi-outlet insulated connector bars, mechanical socket and core compression system, transformer stud connectors, over-current protection devices and explosion-proof protective shells

- Tools and compounds – hydraulic presses, pumps, dies and the new ConductaClean®

The conductor accessories facility has also built an impressive record of environmental stewardship with a recycling rate for paper, wood, metal and plastic exceeding 90 percent, an aggressive storm damage expedite program and a carbon footprint effort aimed at reducing total energy each year by three percent.

We are committed to taking a proactive approach to our customers’ needs, acting with integrity and delivering as promised. AFL understands that it is about quality products and building a strong relationship with every customer.